Chilling processing equipment refers to machinery and systems used in food processing facilities to rapidly reduce the temperature of food products, typically after cooking or processing. Chilling is an essential step in food preservation as it slows down the growth of microorganisms and helps maintain the quality and freshness of the products.

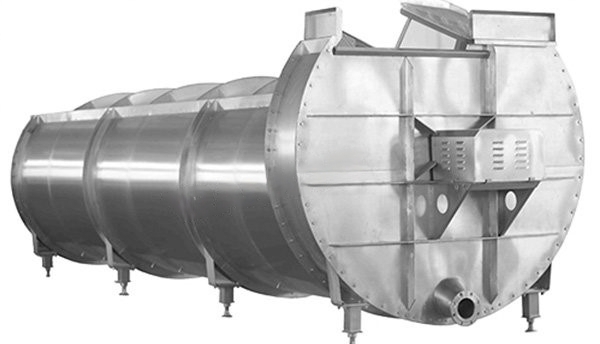

Chilling processing equipment can include a variety of devices such as blast chillers, immersion chillers, plate chillers, and tunnel freezers. These machines are designed to quickly lower the temperature of food items to safe levels, ensuring that they remain safe for consumption and have an extended shelf life.

In poultry processing, for example, chilling equipment may be used to rapidly cool down freshly processed chicken carcasses before packaging to prevent bacterial growth and maintain product quality. Similarly, in the seafood industry, chilling equipment is crucial for preserving the freshness of fish and seafood products.

Overall, chilling processing equipment plays a vital role in the food industry by ensuring food safety, extending shelf life, and preserving the sensory attributes of food products.